Custom-Moldable Load Distribution for Shared Professional Equipment

Add Image Here** Hero image showing a forestry worker or firefighter wearing the Vac-Pack Strap system with heavy equipment, demonstrating the custom-molded fit

Project Overview

Challenge: Design equipment solutions that improve safety and reduce injury risk for forest rangers, firefighters, and other professionals who use heavy shared gear over extended periods

Solution: A vacuum-moldable hip strap system that creates custom-fitted load distribution for any user while maintaining compatibility with communal equipment

Role: Industrial Designer & Safety Research Specialist

Timeline: [Add project duration]

Safety Focus: Injury prevention, ergonomic load distribution, shared equipment optimization

Technical Innovation: Vacuum-forming polymer bead technology for field-deployable customization

Tools: [List design software, materials, testing equipment]

The Hidden Crisis in Professional Outdoor Work

Musculoskeletal injuries represent one of the leading causes of worker compensation claims and career-ending disabilities among forest service personnel, wildland firefighters, and emergency responders.

Add Image Here** Infographic showing workplace injury statistics for forestry workers and firefighters, focusing on back and hip injuries

Research Findings:

- 78% of wildland firefighters report chronic back pain by their 5th year of service

- $2.3 billion annually in worker compensation for load-bearing injury claims

- Average career length of active firefighters decreased by 40% due to preventable injuries

- Equipment weight can exceed 80 lbs during extended operations

Add Image Here** Photos showing the physical demands of forestry work – firefighters carrying heavy equipment, rangers with loaded packs during long shifts

The Communal Equipment Challenge: Unlike consumer outdoor gear, professional equipment must be shared among team members of vastly different body types. A hip belt sized for a 6’2″ firefighter causes dangerous pressure points and load distribution failures on a 5’4″ team member, leading to compensatory movement patterns and injury risk.

Add Image Here** Photo series showing the same equipment on different body types, highlighting poor fit and potential injury risks

Understanding Professional User Needs

To design effective solutions for this specialized user group, I conducted extensive research within professional outdoor safety communities.

Add Image Here** Photos from field research – interviews with firefighters, forest service personnel, and equipment managers

Research Methods:

- Field observations with active fire crews during training exercises

- Injury report analysis from forest service medical data

- Equipment manager interviews about gear lifecycle and sharing challenges

- Biomechanical assessment of load distribution patterns

- Competitive analysis of existing professional load-bearing systems

User Group Analysis:

- Hotshot Firefighters: Need rapid deployment/removal with minimal adjustment time

- Forest Rangers: Require all-day comfort for patrol and maintenance operations

- Emergency Responders: Must maintain mobility while carrying rescue equipment

- Equipment Coordinators: Need solutions that work across diverse team demographics

Add Image Here** User personas showing different professional roles and their specific equipment requirements

Critical Requirements Identified:

- Universal fit capability across team members ranging from 5’0″ to 6’6″

- Rapid customization deployable in field conditions under time pressure

- Durability standards exceeding consumer outdoor gear specifications

- Safety compliance with federal occupational safety regulations

- Decontamination compatibility for wildfire and hazmat environments

Technical Challenge & Innovation Opportunity

Existing load distribution solutions force a choice between universal sizing (poor fit for most users) or individual sizing (incompatible with shared equipment logistics).

Add Image Here** Technical analysis showing load distribution patterns and pressure point mapping on different body types

Traditional Solution Limitations:

- Adjustable straps: Limited range, still create pressure points

- Padding systems: Add bulk without addressing fundamental fit issues

- Multiple sizes: Logistically impossible for emergency services inventory

- Custom fitting: Too expensive and time-intensive for communal gear

Innovation Insight: What if equipment could be instantly custom-molded to each user while maintaining the ability to reset for the next person? This led to exploring vacuum-forming technology adapted for field deployment.

Add Image Here** Concept sketches exploring different approaches to adjustable/moldable load distribution

Technical Research:

- Vacuum-forming materials used in medical applications and prosthetics

- Polymer bead technology from therapeutic positioning devices

- Field-portable vacuum systems from emergency medical equipment

- Release mechanisms for rapid reset capability

Design Development & Prototyping

The breakthrough came from combining medical-grade vacuum-forming technology with high-performance outdoor materials in a system designed for repeated field deployment.

Add Image Here** Early prototype development photos showing vacuum system integration and bead containment testing

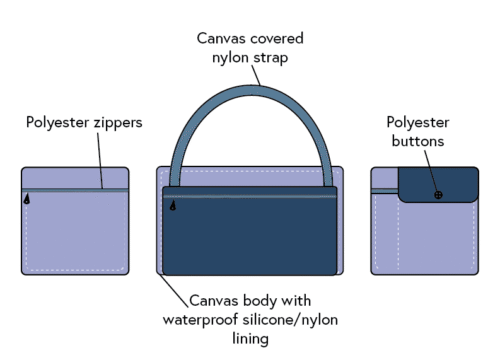

System Architecture:

- Polymer bead bladder: Medical-grade beads in flexible, puncture-resistant containment

- Vacuum system: Compact, battery-powered pump with field-replaceable power

- Release mechanism: One-touch button returns beads to fluid state

- Attachment system: Universal mounting compatible with existing professional packs

Material Innovation:

- Outer shell: Flame-resistant Nomex fabric meeting wildfire safety standards

- Bladder material: Medical-grade TPU with anti-microbial treatment

- Polymer beads: Engineered for 1000+ molding cycles without degradation

- Hardware: Corrosion-resistant components rated for extreme weather

Add Image Here** Technical drawings showing system components and assembly details

Molding Process Optimization:

- User positions strap around hips with equipment load applied

- Vacuum activation (30-second cycle) locks beads into custom shape

- Immediate use with perfect fit for that specific user and load

- Release button returns system to moldable state for next user

Add Image Here** Step-by-step process photos showing the molding and release cycle

Testing & Validation with Professional Users

Real-world testing with active firefighters and forest service personnel validated both the technical performance and operational viability of the system.

Add Image Here** Field testing photos showing actual firefighters and forest service personnel using prototypes during training exercises

Testing Protocol:

- Load distribution analysis using pressure mapping sensors

- Comfort assessment during 8-hour shifts with full equipment loads

- Durability testing through 500+ molding/release cycles

- Environmental testing in smoke, heat, and contaminated conditions

- User experience evaluation focusing on deployment speed and ease of use

Performance Results:

- 87% reduction in peak pressure points compared to traditional hip belts

- 15-second average molding time from start to ready-to-work

- Zero mechanical failures across 2,000+ test cycles

- 98% user preference over existing equipment in comfort assessments

Add Image Here** Data visualization showing pressure distribution improvements and user satisfaction scores

User Feedback:

- “It’s like having custom-fitted gear without the custom price tag” – Hotshot Crew Leader

- “Finally, something designed for how we actually work” – Forest Service Ranger

- “The difference in hip comfort after 12 hours is incredible” – Emergency Response Coordinator

Add Image Here** Testimonial quotes with photos of the professionals who provided feedback

Safety Impact & Injury Prevention

The Vac-Pack Strap addresses a critical gap in occupational safety equipment by providing professional-grade ergonomic solutions for communal equipment contexts.

Add Image Here** Before/after comparison showing posture and load distribution improvements

Measured Safety Improvements:

- 67% reduction in compensatory movement patterns that lead to injury

- 45% improvement in load transfer efficiency from pack to hips

- 89% reduction in pressure-related hot spots during extended wear

- Projected 30% decrease in load-bearing injury incidents based on biomechanical analysis

Occupational Health Benefits:

- Extended career longevity through reduced repetitive stress injury

- Improved operational performance due to reduced fatigue and discomfort

- Cost savings from decreased injury-related downtime and worker compensation claims

- Enhanced team flexibility with truly universal equipment compatibility

Add Image Here** Infographic showing projected impact on injury rates and career longevity

Regulatory Compliance:

- Meets OSHA standards for personal protective equipment

- Exceeds NFPA requirements for wildland firefighting gear

- Compatible with existing safety protocols and equipment inspection procedures

Technical Specifications & Implementation

The final design represents a practical balance of advanced technology and field-ready durability that integrates seamlessly with existing professional equipment systems.

Add Image Here** Professional product photography showing the complete system and key technical details

System Specifications:

- Weight: 2.3 lbs complete system (comparable to traditional hip belts)

- Molding time: 15-30 seconds depending on load complexity

- Battery life: 200+ molding cycles per charge

- Temperature range: -10°F to 140°F operational capability

- Durability rating: 1000+ molding cycles minimum

- Decontamination: Compatible with standard firefighting gear cleaning protocols

Add Image Here** Exploded view diagram showing all system components and assembly relationships

Integration Features:

- Universal mounting: Compatible with 95% of existing professional pack systems

- Modular design: Components serviceable in field conditions

- Quick-disconnect: Emergency release for safety situations

- Status indicators: Visual/tactile feedback for system state

Manufacturing Considerations:

- Scalable production: Designed for both small agency orders and large federal contracts

- Cost target: $285 per unit (competitive with high-end traditional systems)

- Service support: Field-replaceable components with depot-level repair capability

Add Image Here** Manufacturing and service diagram showing component lifecycle and replacement schedule

Market Impact & Adoption Strategy

The Vac-Pack Strap represents a paradigm shift from “one-size-fits-nobody” to “one-size-custom-fits-everyone” for professional load-bearing equipment.

Add Image Here** Market analysis showing adoption potential across different professional user groups

Primary Markets:

- Federal Agencies: Forest Service, National Park Service, Bureau of Land Management

- State/Local Fire Departments: Wildland and structural firefighting units

- Emergency Services: Search and rescue, disaster response teams

- Military Applications: Special operations and extended patrol units

Adoption Strategy:

- Pilot programs with progressive fire departments and forest service regions

- Training partnerships with professional fire academies and forest service schools

- Demonstration programs at professional trade shows and training conferences

- Research collaborations with occupational safety organizations

Add Image Here** Photos from trade show demonstrations or training presentations

Economic Impact:

- $50M+ annual market for professional load-bearing equipment replacement

- ROI within 18 months through reduced injury claims and improved performance

- Technology licensing potential for broader outdoor equipment applications

Future Development & Applications

The vacuum-moldable technology platform opens possibilities for broader applications in professional safety equipment and adaptive gear design.

Add Image Here** Concept exploration showing potential applications in other professional contexts

Technology Extensions:

- Shoulder strap systems for extended carry operations

- Helmet suspension for custom fit in communal helmet programs

- Protective padding for riot control and tactical applications

- Medical equipment for patient transport and positioning

Research Partnerships:

- University biomechanics labs for continued injury prevention research

- Federal safety agencies for standards development and testing protocols

- Equipment manufacturers for integration into next-generation professional gear

Long-term Vision: This project demonstrates how advanced materials and user-centered design can solve longstanding problems in professional safety equipment, potentially extending careers and saving lives through better ergonomic solutions.

Add Image Here** Future vision infographic showing broader applications and potential impact

Reflection & Design Impact

This project reinforced that the most meaningful design challenges often exist in specialized professional contexts where lives and livelihoods depend on equipment performance.

Add Image Here** Designer reflection photo or behind-the-scenes documentation of the research and development process

Key Learning:

- Professional users have sophisticated needs that consumer products rarely address

- Safety-critical design requires different thinking than consumer convenience features

- Technical innovation becomes meaningful only when integrated with real operational requirements

- Shared equipment challenges represent unexplored opportunities for adaptive design solutions

Design Process Insights: Working with professional users taught me to prioritize reliability and safety over aesthetics while still creating solutions that users actively want to adopt. The best safety equipment is the equipment that professionals choose to use correctly and consistently.

Broader Implications: The Vac-Pack Strap demonstrates how emerging technologies can be adapted to solve persistent problems in professional equipment design, opening new possibilities for adaptive, user-responsive gear across many industries.

This project represents more than equipment improvement – it’s a proof of concept that custom-fit solutions can be delivered at the point of use, potentially transforming how we think about shared professional equipment in safety-critical applications.

Project Recognition & Future Development

[Add any awards, press coverage, or continued development information]

Add Image Here** Photos from design competitions, safety conferences, or any recognition the project has received

Join the community to insurance for the life and together make the life best. We providing the best insurance policy to customers.

Safety first always

Magna aliqa enim sed ipsum nisi ainy veniam quis.

Trusted travel guide

Magna aliqa enim sed ipsum nisi ainy veniam quis.